PP/HDPE

Woven Fabric

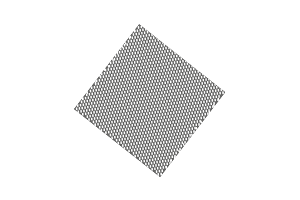

Our HDPE /PPWoven Fabric is a robust and versatile material crafted from high-quality polypropylene or polyethylene thread. This fabric is produced by weaving flat yarns, known as poly tapes, on circular looms, resulting in a strong and stable tubular form. Available in various widths, colors, and mesh sizes, our polypropylene woven fabric is customizable to meet specific application needs. It is 100% reusable and recyclable, non-toxic, and offers exceptional strength and tear resistance. Suitable for a wide range of applications, including packaging, protection, and waterproofing, this fabric combines durability with excellent printability, making it an ideal choice for industries such as packaging, agriculture, and construction.

- Various Fabric Colors

- UV Stabilization

- Substrate Lamination

- High Quality Printing Options

Our Polypropylene Woven Fabric is a durable and versatile material, perfect for various industrial and packaging applications. Made from strong polypropylene (PP/HDPE) or polyethylene thread , this fabric is created by weaving flat yarns, known as poly tapes, together. These poly tapes are woven on a circular loom in two directions – warp and weft (also called fill and pick), forming a stable and reliable tubular fabric.

Once woven, the fabric can remain in its tubular form or be slit to convert it into a flat fabric. This woven fabric is either used directly in its raw state or further processed into other products like bags and geotextile.The flexibility of PP woven fabric makes it ideal for different uses. We can customize the fabric based on width, color, mesh, tape denier, and tape width to meet your specific needs. Whether you require it for packaging, agriculture, or construction, our woven fabric can be tailored to handle different loads and withstand tough conditions.

Our polypropylene woven fabric offers a range of advanced features to suit diverse industrial needs. Whether you’re in packaging, construction, or agriculture, this fabric is designed for durability, customization, and performance.

- Countless Color Options: We offer a variety of fabric colors, including 100% transparency, with the ability to match PMS shades based on customer requirements.

- Customizable Width and Weight: Our pp/hdpe fabric comes in a wide range of widths and weights, allowing for precise customization to meet different needs. Our fabric width range includes Circular fabric from 18 cm to 223 cm and Flat fabric up to 500/510 cm.

- Anti-Skid or Flat Weave: Choose between anti-skid or flat weave options depending on the application.

- UV Stabilization: With UV stabilization lasting up to 3000 hours or 2 years of outdoor exposure, this fabric is built to withstand harsh environmental conditions.

- Ultrasonic Welding: The uncoated flat fabric edges are sealed with ultrasonic welding to prevent tape fraying, increasing longevity and neatness.

- Extrusion Coating Finish: Available in matte finish or gloss finish, offering a superior look and feel.

- Substrate Lamination: Fabrics can be laminated with various substrates like BOPP film, LDPE film, Kraft Paper, or Non-woven SBPP fabric for extra strength.

- Printing Options: We offer flexographic surface printing up to 6 colors and rotogravure printed BOPP laminated fabric with up to 9C colors for vibrant, high-quality branding.

- Specialized Fabrics: Choose from anti-static or flame-retardant fabric for specific industrial applications.

- Fabric Forms: Available in C-fold or U-fold options, providing versatility in packaging and applications.

- Metal Detection: All fabric undergoes metal detection before dispatch to ensure quality and safety.

- Packaging: We provide flexible packaging solutions, including paper, PVC, or metal cores, and options like floor-loaded master rolls or palletized small rolls.

- Core Protection: Additional plastic core plugs are available for extra protection during transport and storage.

Our polypropylene woven fabric provides a multitude of advantages, making it an ideal choice for various applications across industries. Here are some of the key benefits:

- 100% Reusable and Recyclable: This fabric is designed for sustainability, allowing for multiple uses and being fully recyclable at the end of its life cycle, reducing environmental impact.

- Non-Toxic: Safe for both users and the environment, our PP/HDPE woven fabric is non-toxic, making it suitable for applications that require safe handling, including food packaging.

- High Strength and Tear Resistance: With its robust construction, this fabric offers exceptional strength and tear resistance, ensuring it can withstand heavy loads and rigorous handling without compromising integrity.

- Good Printability: The surface of our polypropylene woven fabric is optimized for high-quality printing, enabling vibrant colors and clear designs that enhance branding and product visibility.

Our pp/hdpe woven fabric is highly versatile and suitable for a wide range of applications across different industries. Here are some of the primary uses:

- Packaging: This fabric is widely used in packaging solutions, providing durable and reliable options for transporting goods, including bulk materials, food products, and industrial chemicals.

- Protection: With its strong construction, PP/HDPE woven fabric is ideal for protective coverings, shielding items from dust, moisture, and physical damage during storage and transit.

- Water Resistant: The fabric’s excellent water resistant properties make it suitable for applications requiring water resistance, such as outdoor covers, and agricultural uses, ensuring that contents remain dry and protected from the elements

| Specification | Details |

| Fabric Width | Customizable options available (Our fabric width range includes Circular fabric from 18 cm to 223 cm and Flat fabric Up to 500/510 cm.) |

| Length | Varies based on application needs |

| Fabric GSM | Range from 50 GSM to 240 GSM |

| Colour | Countless possibilities, including PMS shades |

| Mesh | Available in various mesh sizes |

| UV Stabilization | Up to 3000 hours (2 years outdoor exposure) |

| Printing | Flexographic printing up to 6 colors, Rotogravure printing up to 9C colors |

| Lamination | Substrate lamination with BOPP film, LDPE film, Kraft paper, Non-woven SBPP fabric |

| Micro Perforation | Available for enhanced breathability |

| Packing | Available in Floor Loaded master rolls or Palletized small rolls; options for paper, PVC, or seamless metal cores |

Why Choose Our PP Woven Fabric?

Choosing our PP Woven Fabric means investing in quality, versatility, and sustainability. Here’s why our product stands out:

- Superior Quality: Our fabric is made from high-grade polypropylene, ensuring high strength, tear resistance, and durability. This means your products are protected, whether in packaging or during transportation.

- Customizable Options: With a wide range of colors, widths, and finishes, our polypropylene woven fabric can be tailored to fit your specific requirements, ensuring that you get exactly what you need for your applications.

- Reusable/Recyclable: We prioritize sustainability. Our fabric is 100% reusable and recyclable, making it a responsible choice for environmentally-conscious businesses looking to reduce their carbon footprint.

- Safety First: Our non-toxic fabric is safe for various uses, including food packaging, ensuring that you can use it with confidence in any application.

- Versatile Applications: From packaging and protection to waterproofing, our fabric is suitable for a wide array of industries, making it a multifunctional solution for your business needs.

- Excellent Printability: Enhance your branding with high-quality printing options available on our fabric, allowing for vibrant designs that attract attention and communicate your brand effectively.

- Commitment to Customer Satisfaction: We are dedicated to providing exceptional customer service, from product selection to after-sales support, ensuring a smooth and satisfying experience.

Our Products

Request a Quote

Fill out the form and our team will get back to you.