Menu

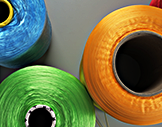

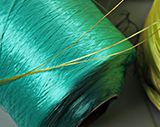

Polypropylene Multifilament Yarn is produced by extruding polymer through spinnerets and combining the extruded filaments together before winding to make it a yarn. Normally these filaments are intermingled by an air vortex to stabilise the extruded filaments and prevent entanglement during unwinding. The yarns can be further twisted to increase its abrasion resistance during processes like sewing.