Menu

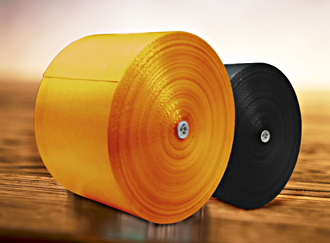

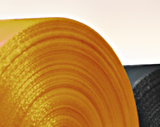

Woven Polypropylene or Polyethylene fabrics are made by weaving flat yarns, commonly known as Poly tapes. Poly tapes are woven together on a circular weaving loom from two directions – warp and weft (also called fill and pick) into a stable tubular fabric form. The finished fabric is woven in a tubular form and can be slit and converted to a flat form also. These fabrics are used directly for various end applications or used as raw material for further converting into different products.

Different fabric qualities can be produced with a combination of width, color, mesh, tape denier, tape width etc.